Rails & Trolleys

Altrac is an adaptable, low-maintenance and safety-tested rail system that can be tailored to virtually any application.

Get a FREE Estimate

Rail Features

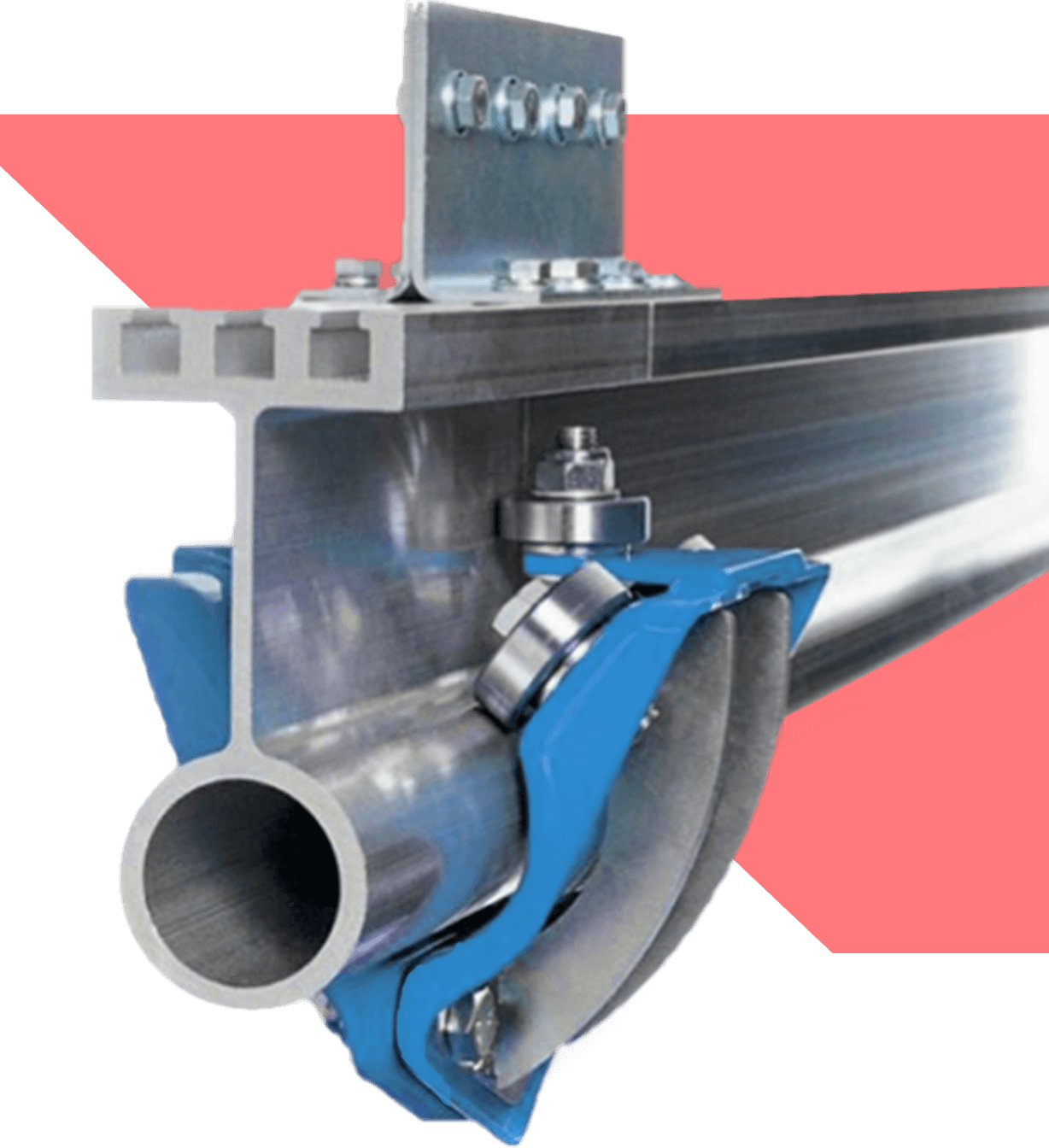

Altrac’s pipe trolley design is fundamentally different than competing rail systems.

Trolley wheels maintain consistent contact with the rail surface which results in smoother running and quieter operation than enclosed track and I-beam trolley rails.

Altrac is an inherently self-cleaning system that will not corrode, making it the lowest maintenance option. This adaptable, safety-tested rail system can be tailored to virtually any application.

Trolley Features

Bracket Systems

The key to the Altrac System is the range of standard brackets and mountings, plus the provision of ’T’Slots in the extruded track section upper flange to allow the use of captive nut fasteners. The three slots give unlimited scope for positioning of suspension brackets and mounting locations. This also provides easy mounting of ancillary equipment such as collector rails, catenary systems, electrical equipment, air lines and fittings.

A full range of structural brackets is available to easily and safely install and support the complete system. All that is required is a single spanner and an electric drill. The system being lightweight and modular can be quickly and easily installed allowing for future modification, extension or relocation. All brackets and fixtures are zinc plated for corrosion resistance. Fasteners are grade B. Brackets and mountings are supplied complete with rivets (where necessary), bolts, nuts and washers.

Bracket Models

AT03 Single Bolt Hanger

550lb Max CapacityAT02 Two Bolt Hanger

1,100lb Max CapacityAT11 Beam Clamp

1,100lb Max CapacityAT01 Splice Kit

Step 01

Step 02

Step 03

Overhead Track Systems

Altrac can provide a full range of component assemblies to enable the design and installation of overhead track systems. These systems can range from single bypass or turn live loops to complex, multi-lane, high-density storage systems.

Used in conjunction with an array of standardized Trac Trolley Stops, Holdbacks, and Anti-runback devices, safe, efficient and cost-effective solutions can be engineered from this range of equipment.

Altrac

is our flagship product which can be tailored to any project. The T slots along the top of the rail allow brackets to be easily attached and adjusted on the spot during installation. The track can also be easily extended with the extension kit.

StrongBac05

StrongBac in conjunction with Altrac makes for an even stronger system. The resulting increase in section properties allows systems to be upgraded from 275lbs to 2,200lbs and/or span capacities to be doubled.

StrongBac50